Ivory board paper, also known as solid bleached sulfate (SBS) paperboard, typically has the following chemical composition:

Cellulose Fibers: Derived from wood pulp, usually hardwood or softwood fibers, which provide strength and structure to the paperboard.

Fillers: Calcium carbonate (CaCO3) or kaolin clay are often used as fillers to improve smoothness, opacity, and printing properties.

Binders: Various binders such as starch or synthetic binders may be added to enhance strength and bonding between fibers.

Additives: These include sizing agents to control ink absorption, wet strength additives, and coatings (e.g., clay coatings) to improve surface properties.

Comparatively, ivory board paper differs from other types of paper like kraft paper or recycled paper in several ways:

Composition: Kraft paper is typically made from unbleached wood pulp, which gives it a natural brown color and different texture compared to the bleached and smooth surface of ivory board paper.

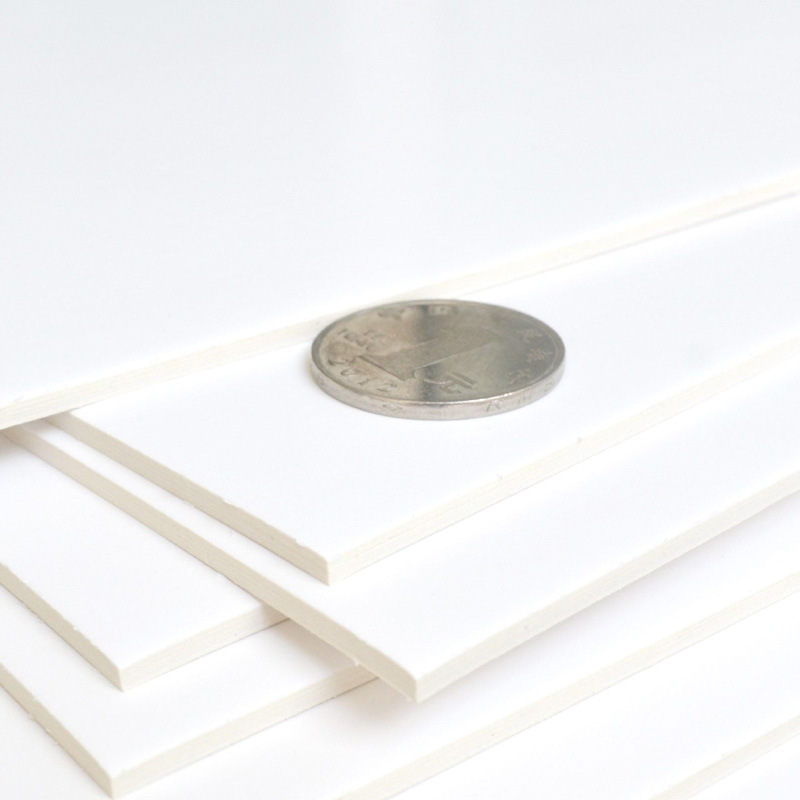

Strength: Ivory board paper, due to its refined fibers and often thicker construction, tends to be stronger and more rigid than many types of paper, making it suitable for packaging and high-end printing.

Printing Properties: Ivory board paper is designed for high-quality printing, with excellent ink holdout and smooth surface for vibrant colors, whereas recycled paper may have a more variable surface and absorption characteristics.

Environmental Impact: Ivory board paper generally has a higher environmental impact compared to recycled paper due to its bleaching process and use of virgin fibers, though efforts are made to improve sustainability through sourcing and recycling initiatives.

Understanding these differences helps in choosing the right type of paper for specific applications based on properties such as strength, appearance, and environmental considerations.

English

English عربى

عربى Español

Español